Archive

RSA – Sustainability As A Matter of Survival: 10 Years of Architecture for Humanity

Cameron Sinclair, joint founder of Architecture for Humanity, recieved an award, and spoke at the RSA on November 9th.

It was illuminating to gain some insight into the history, operation and future directions of AfH, direct from Cameron Sinclair. I experienced an immediate, if somehwat stretched, affinity, by discovering he was originally from Peckham. :o)

AfH have a well-established model for participation and sharing of open-source architecture, via the Open Architecture Network. The classic decentralised ‘network’ approach, that Sinclair quoted as inspiring him, is Paul Baran’s model of distributed network nodes, from 1962, which was instrumental in creating the conceptual underpinning of the internet.

So, the aim is to decentralise, share and participate. You then get a multi-nodal flow of knowledge and experience. Function, meaning and activity will ‘enculture’ local and dsitributed networks, via skills, materials, techniques and symbolism, working across the spectrum of modern Product Design and Engineering. So we’ll explore ways to contribute in traditional Design Engineering (for example, partnering with architecture projects to develop appropriate technology for air-conditioning, heating, ect. for buildings; ‘Jua Kali’ fuel briquette manufacture for micro business, using unpowered machinery and waste organic materials), Industrial Design (for example, input into the useabilty and manufacturability – appropriately – of the above), Service Design (for example, exploring the networks and approaches for marketing and distributing the briquettes) and so on.

How will this work from a design and engineering perspective?

Well, Emily Pilloton has already established another analogous group – Project ‘H’ who approach the domain from a ‘product design’ direction.

The ‘Jua Kali’ prject and Madegood.net will offer another dimension to these, and other existing, models of collaborative, distributed design networks. As an integral part of the Jua Kali project, a collaborative link has been established with Kenyatta University, in Nairobi, where, computing hardware and software will be provided to train designers and engineers in 3D CAD modelling and analysis. This advanced virtual design capability will allow students to compete globally, while improving the efficiency of the design and prototyping cycle locally.

So, a key part of our ‘sharing’ will be making all part, assembly and drawing files available for contributers to use and modify.

The ‘Jua Kali’ project is our main focus and will be for 18 months, but we’ll, hopefully build capacity and bring online some more projects, UK domestic and international, as out network builds.

Again, hopefully, our network will complement those already leading in the vanguard of this movement in design.

BA Product Design – Year 2 – MDX – Visualising the Jua Kali Collaboration (and ‘Madegood’ association) and “How to Participate?”

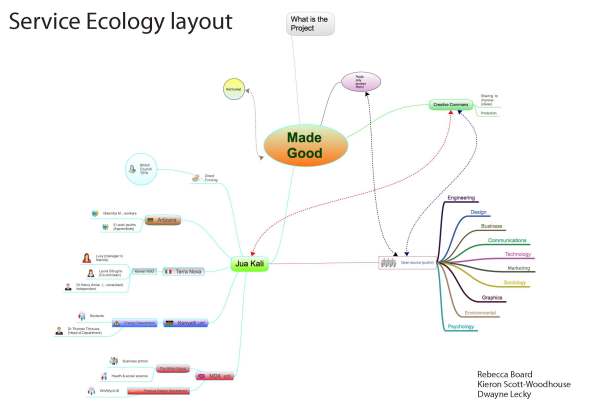

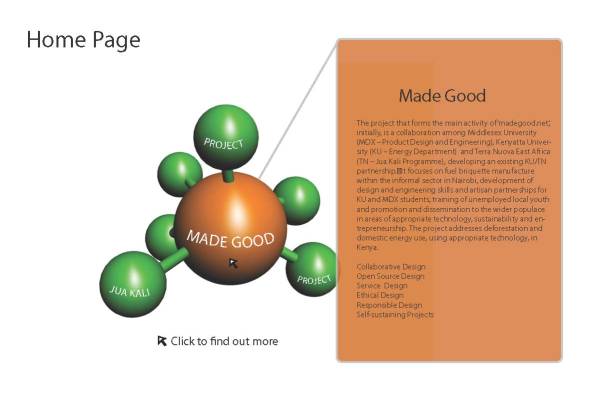

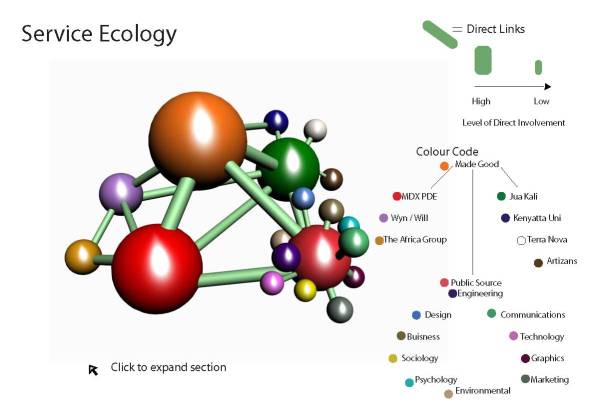

Year 2 students, on the Human Factors, Product Semantics and Interaction Design module, have been designing visualisations of the collaboration – a ‘Service Ecology’ of the ‘actors’ and their inter-relationships, in order to help explain how the project will work and how it can develop. A key element of this is contribution by the public (those not yet involved in the collaborative project). They have also been working on a straightforward way of communicating the need for these contributions and the process of ‘how to participate’.

The following examples were produced by Rebecca Board http://rebeccaboard.wordpress.com/, Dwayne Lecky and Kieron Woodhouse http://kieron-scott.com/:

Further designs, by other Year 2 Students are viewable in ‘Current Proejcts’, along with the Brief they are working to.

Jua Kali Project Contribution – Sam Dempsey

Sam Dempsey, product designer and creator of the ‘Design Democracy’ blog http://designplant.wordpress.com/ has contributed a Solidworks model (parts and assembly) of one of the current versions of the multi-briquette compressors, produced by Jua Kali artisans and Kenyatta University students.

Thanks to Sam.

Created by Sam Dempsey

We will upload the parts and assembly file, for anyone wishing to develop it further.

About

1. The Project – ‘Jua Kali’ / Informal Manufacture Sector Collaboration

The project that forms the main activity of ‘madegood.net’, initially, is a collaboration among Middlesex University (MDX – Product Design and Engineering), Kenyatta University (KU – Energy Department) and Terra Nuova East Africa (TN – Jua Kali Programme), developing an existing KU/TN partnership.

It focuses on fuel briquette manufacture within the informal sector in Nairobi, development of design and engineering skills and artisan partnerships for KU and MDX students, training of unemployed local youth and promotion and dissemination to the wider populace in areas of appropriate technology, sustainability and entrepreneurship. The project addresses deforestation and domestic energy use, using appropriate technology, in Kenya.

2. Activities

The project explores four technical and two communication areas:

1. Technical Analysis of briquette geometry, material composition and emissions. Methods for measuring and mixing of required ingredients.

2. Optimisation of briquette compression presses.

3. Optimisation of shredding and pulping machinery, for preparation of composite ingredients.

4. Optimisation of consumer stoves.

5. Development of a open-source web-based information community.

6. Development of innovative strategies to promote briquettes.

3. How will this project help?

In 40 years, Kenya’s forest cover has depleted from 11 to 1.5%. This is a direct result of a burgeoning population (about 35 million, 2008) using wood products as fuel. With increase in fossil fuel prices more people revert to “cheaper” wood-based fuels and/or burning toxic waste. 56% of Kenyans, surviving on less then 1USD/day, are uninformed on toxicity of burning synthetic waste. Tree felling, insufficient reforestation and inadequate supply of affordable alternative fuels, further compromise forests.

Beside the massive environmental degradation and habitat loss, there is also an increased number of youth and of women-headed households with scarce income generation opportunities and conflicts arising from scarce resources. About 51% of the residents of Nairobi live in the slums, 60% of this population is made up of people below 24 years (UN Habitat). Given the number of youth and the increasing need for them to support their own livelihoods, new income-generating activities are essential, especially when they contribute to other rapidly emerging problems – that of the depletion of Kenya’s forest resources.

However, efforts to enhance briquette use are slow due to inefficient production systems that fail to sustain markets.

In a timescale of 12 months, through the optimisation of the production, it will be possible to produce briquettes at competitive prices and low green gas emissions, offering an alternative to charcoal. At the same time it will become a new income generating activity for people in slums. Materials needed are available. The process is easy to teach and has a proven record in Kenya. It involves harvesting leaves and other organic waste materials that are compressed into briquettes, using a simple wooden pressing machine. The press itself is easy to construct and can be made by any competent carpenter.

The production systems of briquette could be enhanced through the optimisation of technology of briquette machines (such as press, shredders etc.) and stoves using designs already produced by the KU students in collaboration with TN and Jua Kali artisans in the past years, making them more affordable. Building on TN and KU past experience, the partnership with MDX will boost institutional linkages with informal sector of the Jua kali artisans in furthering technology towards environmental conservation. The linkages between the formal and informal sector will also foster socio-economic development through SMEs enhancement, jobs opportunities creation and promotion of interaction among artisans and university students.

4. What we’ll be doing

Modelling and analysis of designs using 3D CAD systems (Solidworks) to allow optimisation of designs, faster, less resource intensive development cycles and effective communication of detail and design intent.

We’ll approach this in an open-source manner. Designs will be published onto madegood.org and refinement, suggestion and redesign from virtual collaborators will be encouraged.

A first model of one of the existing briquette compression machines, by Sam Dempsey, a MDX PDE Product Design graduate http://designplant.wordpress.com/ is shown above.

5. Who are we?

See ‘Us’ in side bar, for details.

6. Images of fieldwork in Nairobi

http://www.flickr.com/photos/30542236@N04/sets/72157608019524592/

7. Open-source approach

We are making all our content available through the Creative Commons scheme. We are attaching an ‘Attribution-Non-commercial-Share Alike 2.0’ licence to all copyrightable content.

This work by https://madegood.wordpress.com/ is licensed under a Creative Commons Attribution-Non-Commercial-Share Alike 2.0 UK: England & Wales License.

“This document is an output from the EPA Project funded by the UK Department for Business, Innovation and Skills (BIS) for the benefit of the African Further and Higher Education Sector and the UK Higher Education Sector. The views expressed are not necessarily those of BIS, nor British Council.”